TIANJIN HOYITE RUBBER PRODUCTS CO.,LTD.

Model: HYT-A53

Crimping range: 1/4"-2"

Stripping range: 1/4"-2"

Dies of quantity: 20pcs (10pcs for crimping , 10pcs for skiving )

ADVANTAGES Of HYT-A53 hose stripping and crimping machine

Hose capacity(max. inner diameter): 1/4" - 2" (4 wire)

Technical Parameter:

| Crimp & skiving Range | 1/4"-2" |

| Crimp force | 5000KN |

| Opening with dies | +30mm |

| Complete Opening | 114mm |

| Master Die Length | 70mm |

| Standard Dies |

20pcs (10pcs for crimping , 10pcs for skiving ) |

| Motor | 4KW |

| Voltages | 220V or 380V or customized |

| Dimensions | 970mm*540mm*1050mm |

| Weight | 310Kgs/320Kgs |

Swage Reference Table pasted on the hose crimping machine.

Each machine offered with a swage reference table to help the users choose the proper die sets when doing crimping.

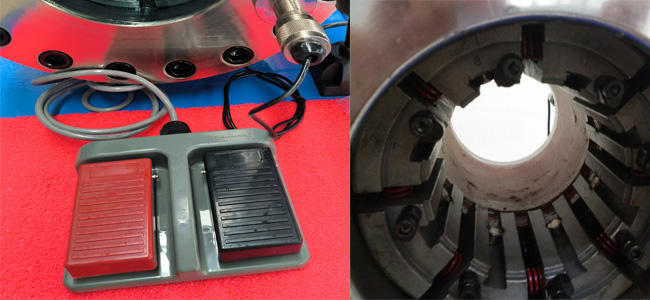

Foot Pedal Available.The foot pedal of A53 is a double function foot pedal. It can control not only the die sets closing, but also controls the die sets opening. So the operator not need to open the die sets by press the button on the panel

High hardness die sets. 20pcs free dies ( 10pcs for hose crimping , 10pcs for hose skiving)

All 51 series offer 10 die sets as standard configuration. It enables the machine to crimp the hydraulic hose from 1/4'' to 2''. Die sets number are marked on the surface, so the user can figure out the die set they need quickly. Special die sets are available on request.

Crimping diameter control Micrometer.

It uses the micrometer designed in China Mainland.

The advantage is it is easy install and take off from the machine. Accuracy up to 0.01mm.

How to crimp hydraulic hose?

1>Preparation: Place the hose on the workbench of the machine and ensure that both ends of the hose are in the appropriate position.

2>Set parameters: According to the size and requirements of the hose, adjust the parameters on the machine, such as crimping width, crimping strength, etc.

3>Start the machine: Start the hydraulic hose crimping machine by pressing the start button or foot switch.

4>Crimping operation: The machine will automatically curl the edges of the hose and use crimping force to fix them together. The operator only needs to observe and ensure the quality and accuracy of the crimping.

5>Complete the work: After the hose crimping is completed, turn off the machine and take out the completed hose.

Additional Information:

Paymets Terms: T/T ( Bank transfer ), Western Union, Paypal , Credit Card, Online pay etc.

Port of Dispatch: Tianjin

Delivery Time: 7~10days

E-mail vitty@hythosecrimpingmachine.com

Tel/Wechat/WhatsApp: +8618202619835